The Alexandra theatres was a fast tracked electrical & mechanical project delivering crucial services on time for the people Redditch, whilst respectfully working in conjunction with various other trades and adhering to the project programme.

This project provided new Endoscopy facilities serving two new operating theatres. A temporary corridor was created to enable the modular theatres to be used whist the traditional building was been completed.

By selecting locally manufactured Thorlux luminaires on this project we were able to deliver on sustainability. Thorlux is proud to manufacture 97% of its luminaires at its facility in Redditch, Worcestershire which is no more than 1 Km from the Alexander Hospital. This allows complete control over the manufacturing process ensuring that negative environmental impacts are minimised whilst conserving energy and natural resources.

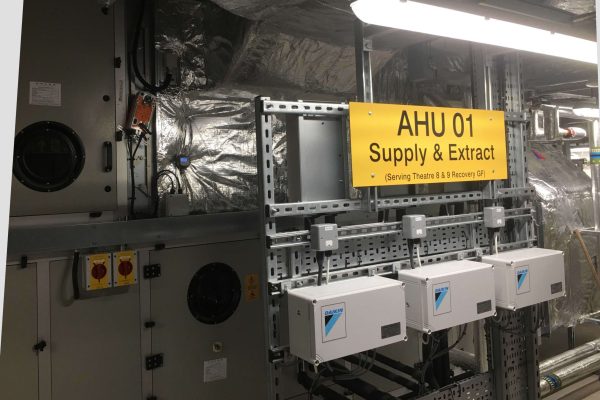

On the mechanical side of the project installing a new AHU, cooled by DX allowed us to increase the energy efficiency within this area.

Electrical Works

All aspects of the electrical installation have been carried out to a high standard as to comply to BS7671: 2018 and as per the installation drawings provided by EXI.

Installation of the latest Thorlux smart scan emergency luminaires which self-test the emergency luminaires to the IPS units that were supplied from Bender UK Ltd.

A new LV panel has been installed in conjunction with the manufacturer Twyver providing Essential LV supplies to all areas as per the schematic drawing provided by EXI.

- Thorlux smart scan lighting

- Thorlux smart scan lighting to the perimeter of the building

- Thorlux smart scan roadway lighting

- MK cable management systems

- Static fire protection devices

- IPS units to provide protection to the treatment rooms

- UPS units

- Damper control circuits

- 185mm parallel Essential supply to feed new LV panel

- Installation of new HV panel

- LV mechanical plant supplies to 1st floor plant room

- BMS integration

- Small power

- LV distribution boards

- Data installation

- Door access control

- CCTV

- Primary and secondary containment

- Nurse call system

- Bedhead trunking

Mechanical Works

- 1 no HTM compliant AHU served by DX for cooling and LPHW for heating for heating coil and frost coil.

- 200 metres of underground pipework from the existing plant room to the new building.

- 3 pumped circuits serving 2 new Theatres, radiant panel circuits and new AHU.

- New domestic water services from existing services within hospital second floor.

- New supply and extract from AHU to all areas.

- BMS integrated onto Trust head end.

- AC into UPS comms room.

- Medical gas serving 6 new bed head locations.

- Full flushing to BSRIA

- Chlorination

- Full air balancing/ validation to HTM 03